Product

TULC

TULC(Toyo Ultimate Can) is a 2-piece can with significantly improved productivity and environmental friendliness, perfected by radically reexamining raw materials and production process. Since its introduction in 1991, TULC has been used for a wide range of products both in Japan and abroad, which is now still evolving with more advanced decoration capability and further weight reduction.

Awards received

-

TULC won “Environmental Resources Cooperation Award” from The Japan Food Journal.

TULC won “Aida Technology Incentive Award” from The Japan Society for Technology of Plasticity.

-

TULC won “Japan Star Award” at Japan Packaging Contest hosted by Japan Packaging Institute.

TULC won “WorldStar Award” form World Packaging Organisation.

-

TULC won “Food Industry Technology Award (Technology & Idea Section)” from Food Industry Journal.

-

TULC won “Nishiyama Commemorative Prize” from The Iron and Steel Institute of Japan.

-

TULC won “Okochi Memorial Award” from Okochi Memorial Foundation.

-

Ready-to-drink coffee packed in mildly-pressurized TULC with liquid nitrogen mist filling method won “Good Packaging Award” at Japan Packaging Contest.

-

aTULC won “Kinoshita Award” from Japan Packaging Institute.

TULC shaped can won “Beverage Packaging Award” at Japan Packaging Contest.

-

aTULC won “Aida Technology Award First Prize” from The Japan Society for Technology of Plasticity.

-

TEC200 won “International Steel Packaging Effectiveness Award Beverage Section First Prize” from APEAL, Germany.

-

Beaded can adopted by JT won “Can of the Year Decoration Technology Bronze Award”, UK.

Development of laminated can utilizing existing 2-piece can production line won “Can of the Year Development Bronze Award”, UK.

Study on LCA evaluation method of TULC won “LCA Society of Japan Encouragement Award” from Life Cycle Assessment Society of Japan.

-

TULC won the Minister of the Environment Prize for Containers and Packaging 3Rs Promotion.

-

sTULC for beer won “Can of the Year Beverage Two-Piece Silver Award”, UK.

-

More environmentally friendly can “190g Lightweight TULC for Vacuum Filling” won the Minister of the

Environment Prize for Containers and Packaging 3Rs Promotion. -

aTULC for beer won “Can of the Year Beverage Two-Piece Gold Award”, UK.

-

sTULC for coffee won “Can of the Year Award 2011“ and

“Can of the Year Beverage Two-Piece Gold Award”,UK. -

TULC with mirror-like label won “Beverage Packaging Award” from Japan Packaging Institute.

TULC with six beads won “Can of the Year Sustainability Award”, UK.

aTULC for beer won “Beverage Innovation Can Award” at Asia Can Tech 2012, UK.

-

Diamond-Cut TULC with mirror-like label won “Can of the Year Beverage Two-Piece Silver Award”, UK.

-

aTULC for wine won “Can of the Year Beverage Two-Piece Gold Award”, UK.

-

Can bottom reform technology “Compression Bottom Reform (CBR)”

technology for aTULC and Aluminum DWI can won “Can of the Year Prototype Gold Award”, UK.

Features of TULC

-

POINT1Friendly to environment, as no water is used during can forming process.

PET film laminated to internal and external surfaces serves as the coolant during can forming process, thus eliminating subsequent washing process and generating almost no solid waste.

-

POINT2Highly capable of preserving product quality, as it allows almost no elution of organic substances or flavor absorption.

PET film laminated to can internal surface has significantly better properties in terms of elution of organic substances and flavor absorption as compared to conventional lacquer coating, retaining the freshness of the products for a long time.

-

POINT3Expanded design options with high quality printing and distinctive can shapes.

In addition to conventional 2-piece can printing (relief printing), TULC can accommodate more precise waterless lithographic printing or labeled can with gravure film, and its can body can be shaped in various patterns, all of which can effectively convey attractiveness of the product to consumers. => Link

-

POINT4The lightest steel can in the industry, contributing to the reduction of negative environmental impact

Together with Nippon Steel & Sumitomo Metal Corporation (currently Nippon Steel Corporation), we developed a light weight can we call “mildly-pressurized can(1).” Its weight of 16.2g (excluding the end) is approximately 6% lighter than conventional pressurized cans, and 40% lighter than the vacuum can(2). It is the lightest steel can in the industry.

Mildly-pressurized can Vacuum can New Conventional Metal thickness 0.170㎜ 0.185㎜ 0.225㎜ Can weight 16.2g 17.3g 26.7g Reduction ratio Over 6% Standard (reference) – About 40% – Standard (reference) Note 1: Mildly-pressurized can

A can whose internal pressure is higher than the atmosphere. Due to this internal pressure, It can retain the strength even if can body wall is thin. A combination of flat bottom and mildly-pressurized filling system allows the use of quality inspection by tapping test for vacuum can.Note 2: Vacuum can

A can whose internal pressure is lower than the atmosphere. It retains strength with the rigidity of the can itself.

Main applications

Beverages that require retort sterilization, such as coffee, tea and soup.

Beverages that do not require retort sterilization, such as fruit and vegetable juice and sports drinks.

Product lineup

| Can type | Body dia | Fill volume | End dia |

| Vacuum | 202 | 160ml | 200 |

| 175ml | |||

| 200ml | |||

| 250ml | |||

| Slightly pressurized |

202 | 200ml | 200 |

[Material] Steel

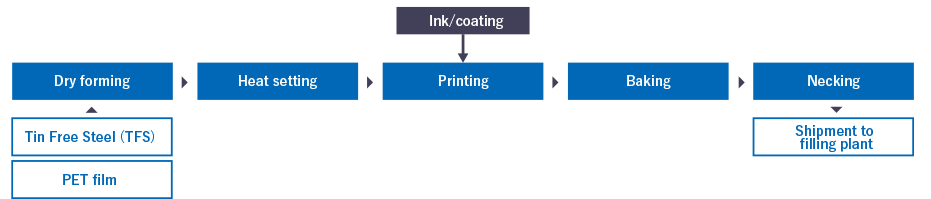

Can making process

Production process of TULC