Toyo Seikan Co., Ltd. (the “Company”) has developed the world’s lightest*1 aluminum beverage can, the 190 ml 202 SOT (Stay-on-Tab) can, which uses only 6.1 g of aluminum per container. The can has been chosen by Coca-Cola for its 185 g Georgia*2 coffee brand can products, and mass production started in the Kanto region in August on a limited basis.

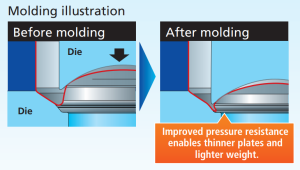

The lightweight design of the world’s lightest aluminum can is made possible by reinforcing the bottom of the can using compression bottom reform (CBR) technology. This marks the first mass production of the 190 ml 202 SOT aTULC (Aluminum Toyo Ultimate Can) with CBR technology.

Furthermore, the world’s lightest can earned a joint Appropriate Packaging Award for the Company and Coca-Cola Japan Co., Ltd in the Packaging Technology category of the Japan Packaging Contest 2024.

*1 According to our research as of August 2024. The weight is calculated when the can is empty, excluding any laminate film on the can body or end.

*2 Georgia is a registered trademark of The Coca-Cola Company.

Part of the Georgia product line uses 185 g lightweight aluminum beverage cans.

Georgia Emerald Mountain Blend, Georgia Golden Drip Bito,

Georgia Platinum Black, Georgia Prime Blend

Using CBR technology, we have reduced the weight of our 190 ml 202 diameter SOT cans by 0.9 g, from 7.0 g to 6.1 g. This lower weight results in an 8% reduction in greenhouse gas (GHG) emissions per can compared to our existing cans. If CBR were implemented in all aluminum beverage cans where applicable, GHG emissions would be reduced by an estimated 40,000 metric tons*3 annually.

*3 Based on the manufacturing records of our existing aluminum beverage cans for fiscal 2022 and the GHG reduction per can for the lightest can in the domestic market.

[Reference] Illustration of a can bottom being formed using CBR

CBR is an innovative technology that allows for both high can-bottom compression strength and lightweight design, surpassing traditional can manufacturing techniques. It contributes to the reduction of GHG emissions by minimizing the use of aluminum materials. We are currently expanding the implementation of CBR across our manufacturing bases nationwide. In addition to the 190 ml can mentioned earlier, we are also using CBR to manufacture aluminum cans for 350 ml and 500 ml products. This initiative aims to promote the adoption of the lightest aluminum cans and further reduce GHG emissions.

For inquiries about this press release, please contact

Nakanori / Kakimoto

Corporate Communication Group

Sustainability Department

Toyo Seikan Group Holdings, Ltd.

(Email) tskg_contact@tskg-hd.com